Low Res

See a more complete gallery of this artwork on the Second String Studios website

Overview

Low Res is a fully custom lighting and art piece made up of 150 light-diffusing cubes mounted vertically in a grid. It can serve as a purely functional structure with brightness and warmth adjustment, or as a creative piece with many different patterns and colors. Each cube is individually addressable and the overall piece can function standalone or run from external ArtNet or DMX input. It is also possible for the patterns running on the wall to react to audio input through integration with LedFx, allowing ’live’ control synced to music.

One of the simple renders I created in order to test different arrangements of the grids

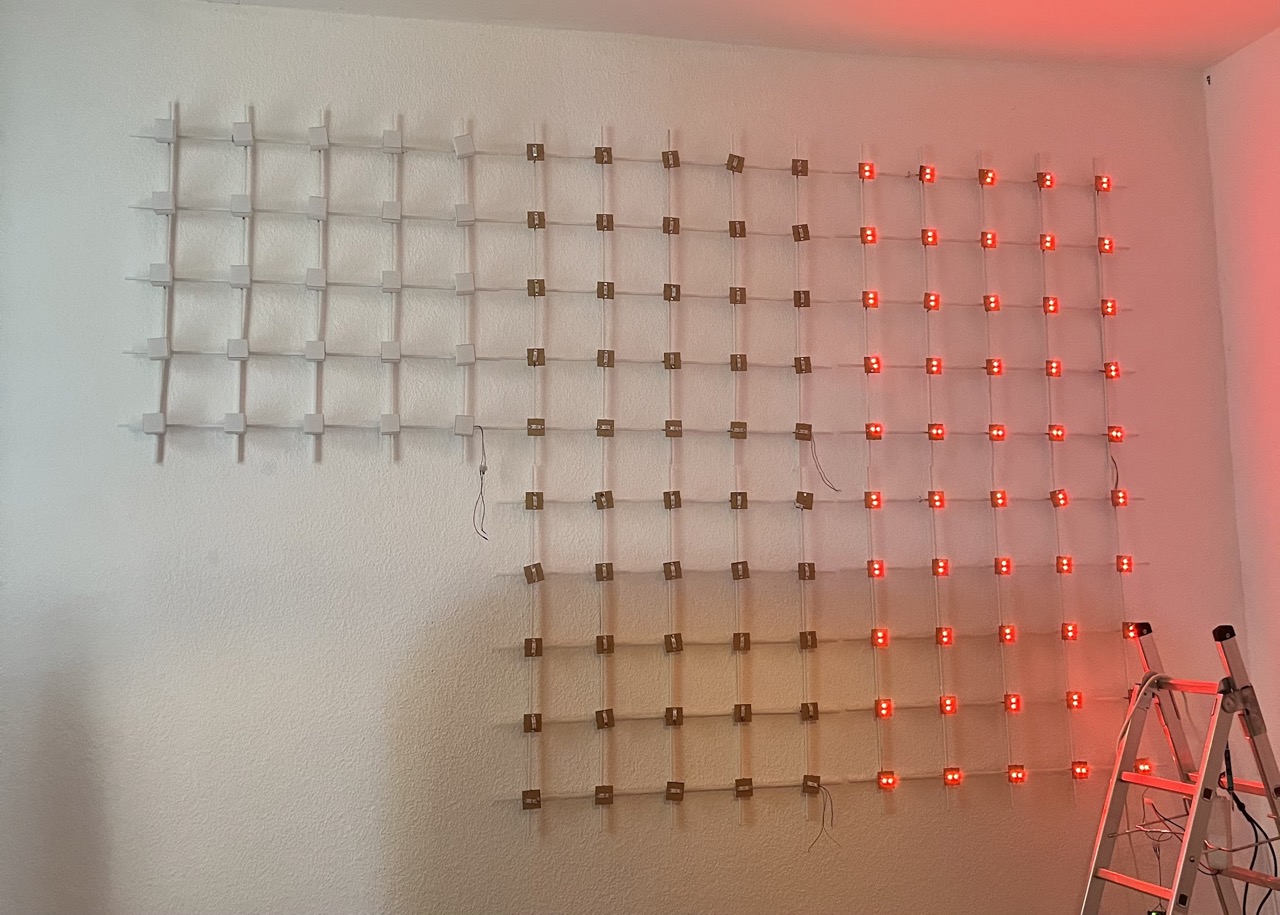

The grid is arranged 15 cubes wide by 10 cubes high. It is built from six individual grids that were then joined together to create a seamless overall appearance.

The base structure of each 5 by 5 grid is made from overlapping plastic U-channel pieces (commonly used as cable trays). Power, ground, and data are all cabled through these U-channels, remaining invisible from the front of the piece.

Closeup of an individual cube assembly

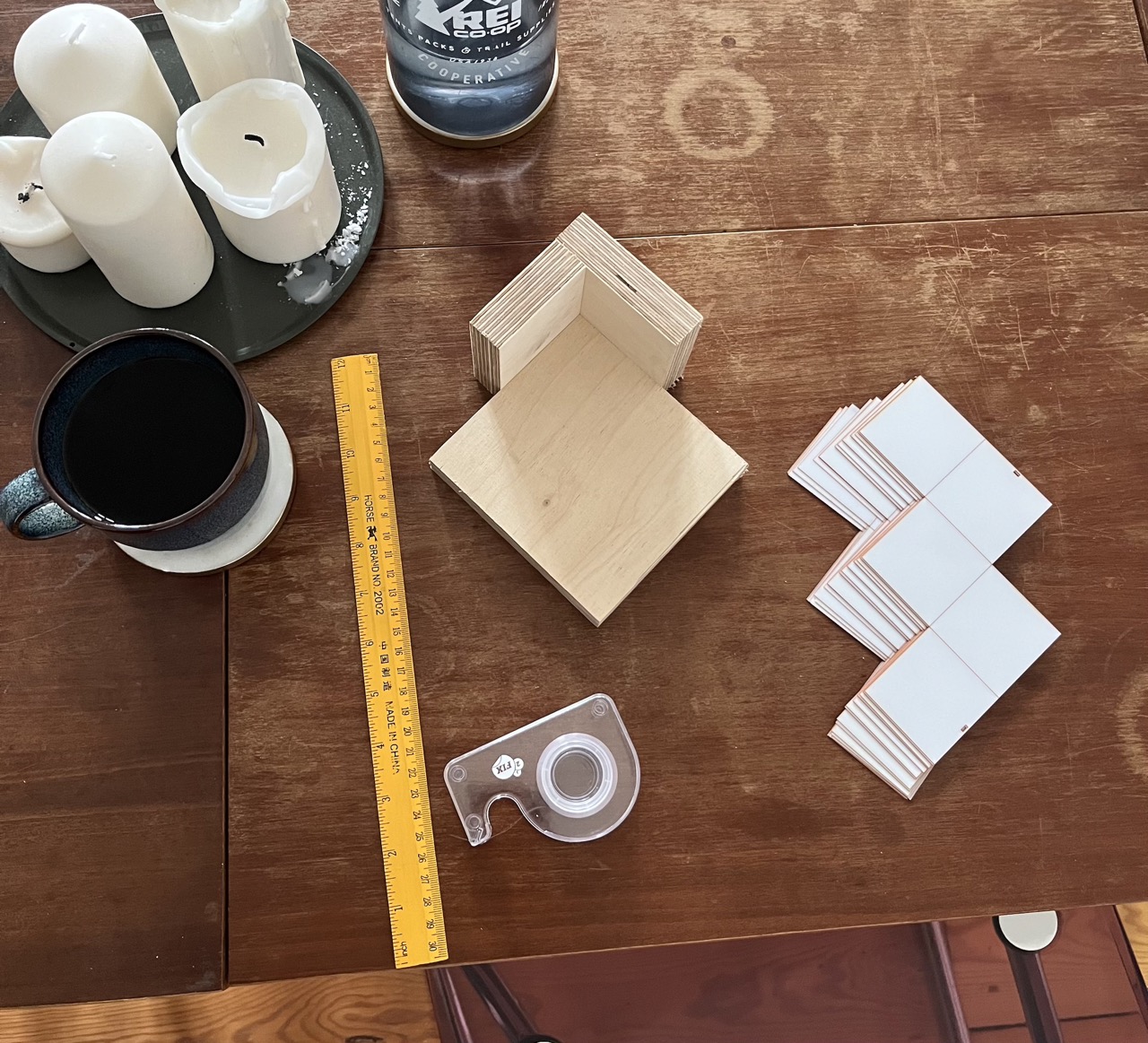

Each cube assembly is made up of a 40mm M3 screw, a spacer, a lasercut cube base, and a washer + nut. The cube body is lasercut from a thin sheet of light-diffusing, plastic-based material (in German, Leuchtkastenfolie), then folded along laser etch marks, taped together, and affixed to two ’ears’ on the lasercut base.

Assembly jig with a set of lasercut diffuser cubes

After testing, I determined that 2 LEDs per cube provided enough light while keeping overall power use reasonable.

Electrical Design

A block diagram of the electrical connecitons throughout the grid

The entire piece is powered by a 100W power supply (5V @ 20A). 20A was chosen from a safe overestimate of current per RGB LED of 60mA, resulting in an expected max current of 18A at full brightness for R, G, and B channels. Each of the three pairs of 5 by 5 grids has an individual power connection coming from a main, thick-gauge power and ground wire.

The cabling within each grid is run with thin-gauge cable to fit in the low-profile U-channels. This caused a greater-than-expected voltage drop for each pair as the power got further away from the injection point, so a second line of power and ground injection was cabled along the ends of each pair of grids. This ‘front and back’ power scheme successfully supports running the grid at all white full brightness with no discoloration in the LEDs.

Partially assembled and hung, running a quick test pattern to ensure connection between each grid pair

The LEDs used are basic WS2812 strip LEDs cut into sections of 2 LEDs.The three inputs and outputs are soldered directly to the LED strip copper pads as they enter/exit through the holes cut into the cube bases.

The most complicated part of the electrical design by far was the PCB pushing the data to the LEDs. There exist many libraries and out-of-the-box hardware solutions for running addressable LED protocols, but I wanted more customization and a more professional solution that I could use for many different applications in the future (without paying hundreds/thousands of dollars for existing off-the-shelf designs).

I designed and built a custom PCB that supports 5-24V input power, up to 5V @ 2A output power, Ethernet communication, 3V3 and 5V GPIO output, and DMX support. Currently for this project, the board is running firmware from the popular WLED project to support many patterns and easy control. The end goal for this board is to run custom firmware to allow full control from either DMX or ArtNet without needing all of the extras from WLED.